FORMIFICIO STF Our Story

Having first followed in the footsteps of his father (Sales Officer for the leading shoe-last manufacturers in Italy from 1932 until the1960s), in 1971, Aldo Tripodi, together with Giuseppe Finesso, took over a small shoe-last workshop in Strà, a town of the Riviera Del Brenta, a few kilometres from Venice, famous for its shoe-making traditions.

As a result of the competence and excellent understanding of the market, the company rapidly became the preferred supplier to many top brands in Italian and international fashion.

Aldo’s own son, Andrea, joined the company in 1992. He is now responsible for the technical and sales departments.

Gianluca Boschetti joined the company in 2008 and was soon co-opted on to the management team. He is now CEO of STF Marche Srl, an associated company that was taken over in 2009.

Generational change was completed in 2011, when Andrea’s sister Alessandra joined the company and took charge of all production operations.

OUR COMPANY

Top Quality in Design and Production

STF's operates two modern factories covering a total land area of 12,000 square metres and occupying 3500 square metres of buildings. The company is characterised by an innate commitment to technical development and organisational efficiency.

STF boasts a large park of advanced machines and systems, developed in-house or in close collaboration with specialist machine constructors. The most important of these are:

Three fully automatic polythene block extrusion lines, with a production capacity of 10 tons in 24 hours.

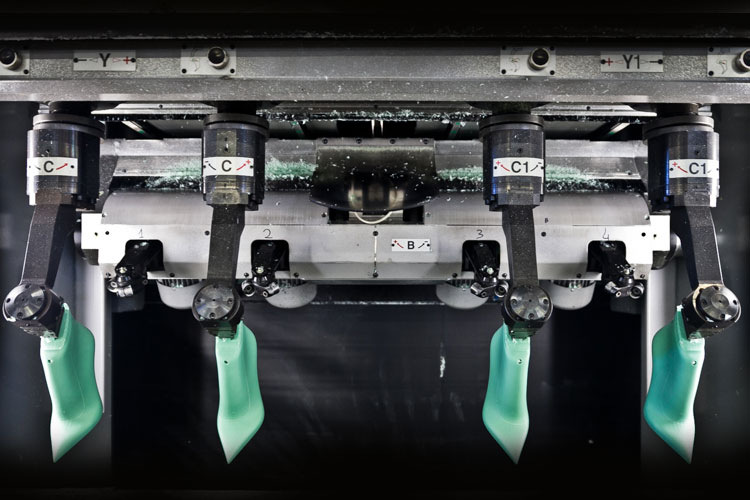

CNC lathes to meet all needs, including the finishing of lasts with toe and heel using NL SDF technology.

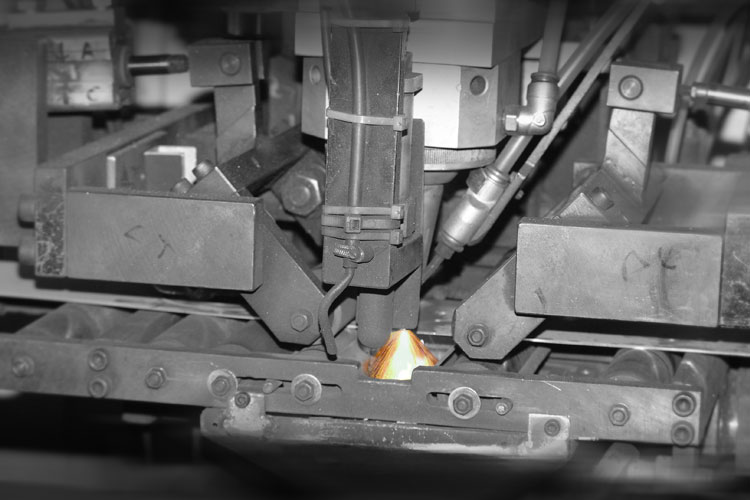

Automatic CNC laser cutting systems for metal plate production.

Advanced production planning and real time process control ensure rapid, reliable response and prompt delivery of samples and production orders.

A coordinated series of checks and tests ensure the total repeatability of samples, series and updates.

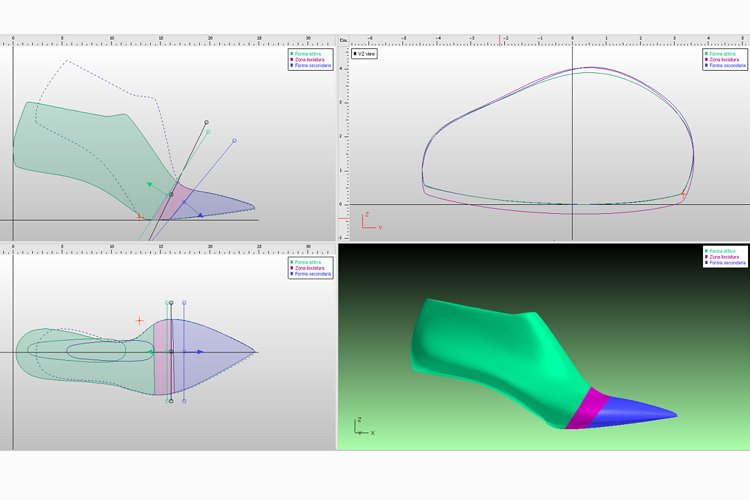

Our large, efficient and expert shoe-lasts modelling section, supported by continuously evolving CAD systems, is capable of handling dozens of requests a day with impressive rapidity.

Ultra-efficient organisation is guaranteed by an advanced IT system and continuously improving proprietary software.